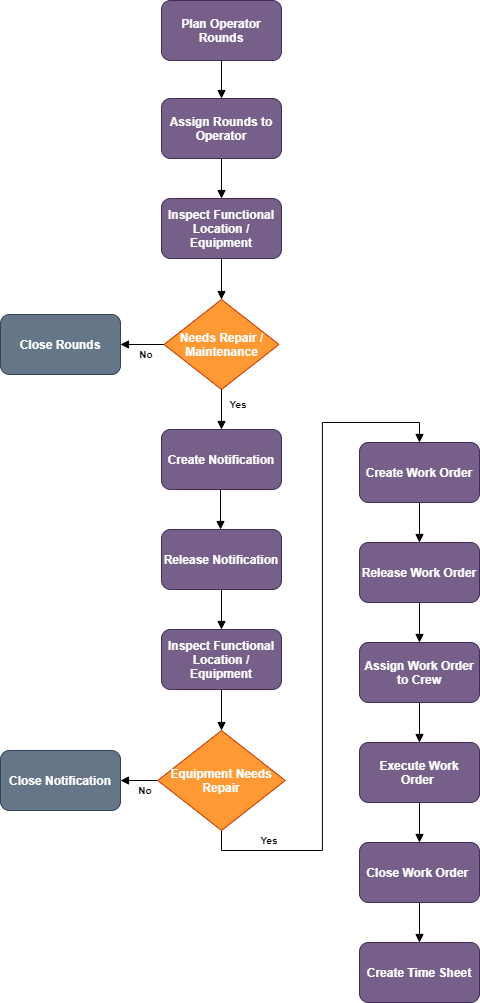

Asset Management Workflow using mWorkOrder

Typical workflow of Enterprise Asset Management using the mWorkOrder application

From planning periodic asset maintenance activities (operator rounds) to creating and managing job works for asset, the mWorkOrder application follows the below workflow to help you reduce machinery breakdowns.

| S. No | Task Name | Link |

|---|---|---|

| 1 | Plan Operator Rounds | Plan and Schedule Asset Monitoring Tasks |

| 2 | Assign Rounds to Operator | Assign and Execute Operator Rounds |

| 3 | Inspect Functional Location / Equipment | View Operator Rounds and Update Due Dates |

| 4 | Close Rounds | View Operator Rounds and Update Due Dates |

| 5 | Create Notification | Create a Notification |

| 6 | Release Notification | Release a Notification |

| 7 | Inspect Functional Location / Equipment | View Operator Rounds and Update Due Dates |

| 8 | Close Notification | Complete a Notification |

| 9 | Create Work Order | Create a Work Order |

| 10 | Release Work Order | Release a Work Order |

| 11 | Assign Work Order to Crew | Add Crew to Work Center and Assign Jobs |

| 12 | Execute Work Order | Execute a Work Order |

| 13 | Close Work Order | Close a Work Order |

| 14 | Create Time Sheet | Create and Use Time Sheets |