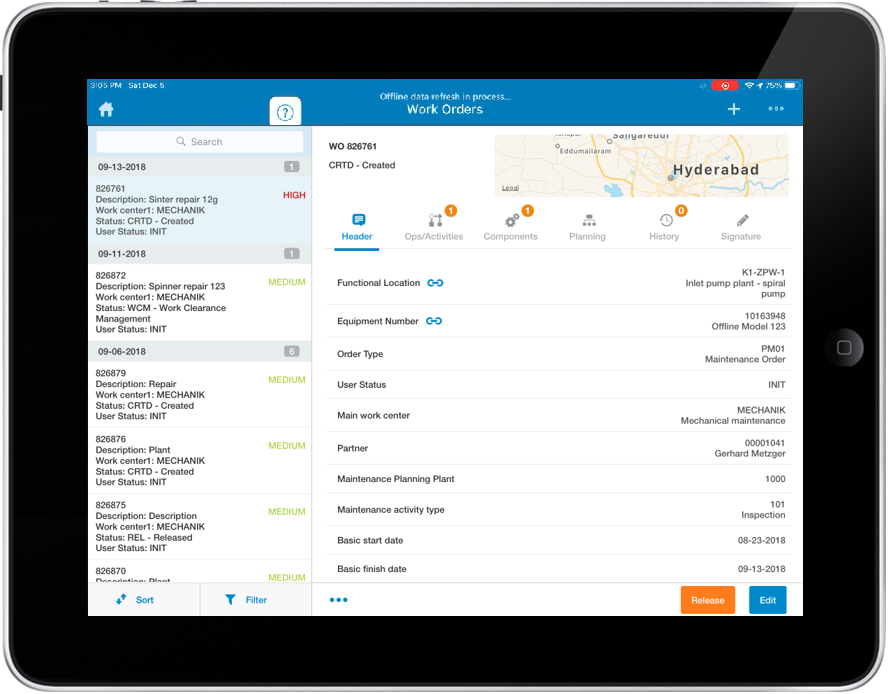

Release a Work Order

Once a Work Order is created, it is assigned to a person/group/team. The person/group/team must then acknowledge their acceptance by releasing the Work Order. Work orders must be released before they are processed by the field technicians. Before you release a work order, check the history of work orders for the equipment or functional location.

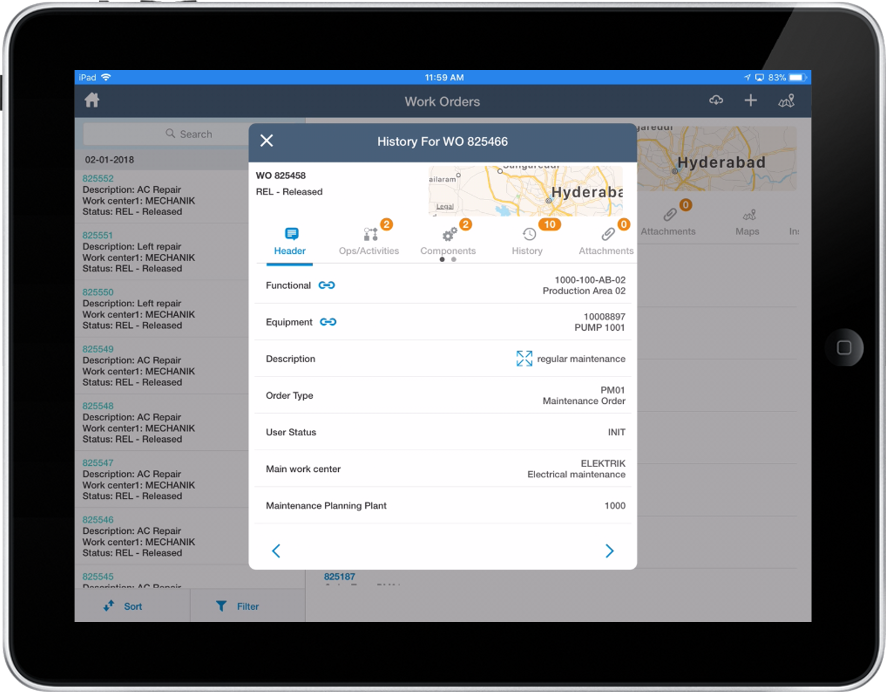

To view the history of Work Orders for Equipment or Functional Location:

- From the left section of the Work Orders screen, search and tap the Work Order for which you want to view the history.

-

Tap the History tab in the right side section of the work orders

screen.

The list of previously created work orders for the equipment or functional location appears.

Figure 1. Work Order History

- The list of previously created work orders for the equipment or functional location appears.

- Select any of the records from the list, to view Header, Operations, Components, Attachments and Forms tabs.

-

Once you confirm no existing work order for an equipment or functional

location, tap Release in the Work Orders screen.

When a Work Order is released, ensure that all necessary parts, operations and documents are available for the maintenance technician to start work, and all required parts are in stock.

If there is an insufficient quantity of spare parts, the application displays a warning message, saying: "Required quantity for Material xxxxxxx is not available in stock. Do you want to proceed?" with options for Yes and No.

Note:This warning message appears in two scenarios:- While releasing the work order.

- While adding a component to a released work order.

Figure 2. Work Order History