Create a Service Notification

Create a service notification, when it is time for service of an equipment or a functional location. When you create a service notification, you select a service partner / vendor detail, select the service required dates and so on.

To create a service notification:

-

In the Home screen, tap Create

icon in the My Notifications area.

Note:You can also tap the Create

icon in the My Notifications area.

Note:You can also tap the Create icon in the Notifications screen.

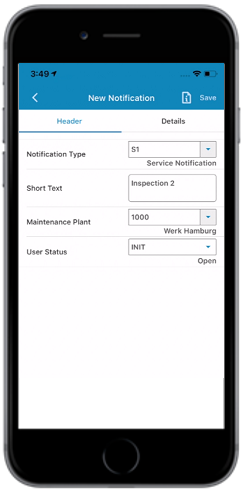

icon in the Notifications screen.Figure 1. Create Service Notification

-

In the New Notification screen, do the following in the Header

tab:

- Notification Type: Select the Notification Type from the list (for example, S1 (Service Notification)).

- Short Text: Enter short description.

- Maintenance Plant: Select the Maintenance Plant from the list. The Equipment list, Functional Location, and Material/Assembly available for the Maintenance Plant is updated in the respective drop-down lists.

- User Status: Auto populates based on configured default settings.

-

In the Details tab, do the following under the Notification

tab:

Note:Fields that are displayed depend on the UI validations configured in RACE. For example, if the UI validation is configured to hide Functional Location field based on Notification Type like M1 then the Functional Location field is not displayed when you select M1 in Notification Type field.

Familiar extensions for Equipment and Functional Location hierarchy such as Technical ID that help you identify assets easily can be configured through RACE. When done, you can also search assets using the extension field data.

- Functional Location: Select Functional Location from the list.

After selecting the functional location, tap the Hierarchy

icon against Functional

Location field and from the pop-up screen select a sub

functional location or an equipment.Note:

icon against Functional

Location field and from the pop-up screen select a sub

functional location or an equipment.Note:- If you tap the Functional Location Hierarchy icon

without

selecting any Functional Location, the application shows an

error.

without

selecting any Functional Location, the application shows an

error. - mWorkOrder supports 30 characters for the Functional Location ID. You can configure SAP for Alternate Labeling to support 40 characters ID.

- If you tap the Functional Location Hierarchy icon

- Equipment No: Select Equipment for the functional location from

the list or, tap the Hierarchy

icon against the

Equipment field and select the equipment.

icon against the

Equipment field and select the equipment. - Planner Group: Select Planner Group from the list.

- Planning Plant: Select Planning Plant from the list.

- Work Center: Select Work Center from the list.

- Crew ID: Select Crew ID from the list.

- Reported By: This field is auto-populated. Tap the field to enter a different name.

- Notification Date: This field is auto-populated. Tap the

Calendar

icon to select a different Notification

Date.

icon to select a different Notification

Date. - Coding: Select Coding from the list.

- Description: Tap the Maximize

icon to enter the description or select the

predefined template. On the pop-up screen tap Templates to select

the template.

icon to enter the description or select the

predefined template. On the pop-up screen tap Templates to select

the template. - Priority: Select Priority from the list.

- Required Start Date: This field is auto-populated. Tap the

Calendar

icon to set a different Required Start

Date.

icon to set a different Required Start

Date. - Required Start Time: This field is auto-populated. Tap the

Clock

icon to set a different Required Start

Time.

icon to set a different Required Start

Time. - Required End Date: Tap the Calendar

icon to select the Required End Date.

icon to select the Required End Date. - Required End Time: Tap the Clock

icon to select the Required End Time.

icon to select the Required End Time. - Breakdown: Select checkbox for breakdown if any.

- Malfunction Start Date: Tap the Calendar

icon to select the Malfunction Start

Date.

icon to select the Malfunction Start

Date. - Malfunction Start Time: Tap the Clock

icon to select the Malfunction Start

Time.

icon to select the Malfunction Start

Time. - Malfunction End Date: Tap the Calendar

icon to select the Malfunction End

Date.

icon to select the Malfunction End

Date. - Malfunction End Time: Tap the Clock

icon to select the Malfunction End

Time.

icon to select the Malfunction End

Time. - Assembly UI Label: Select Assembly UI Label.

- Person Responsible: Select Partners from the list.

This field displays personal name along with the personal number.

- Item Number: Select the item number.

- Risk Assessment: Tap the drop-down to assess the overall risk

level. The Risk Assessment window appears.

In the Risk Assessment window, select the scenario for the category and the probability of occurrence of the scenario. The Overall Risk Level is calculated based on the Risk Level identified for these categories:

- Consequence to People: Helps you analyze the impact of

the incident on people.

- People: Select the scenario that defines the impact on people.

- Likelihood: Select the probable occurrence of the scenario.

- Risk Level: Risk level is auto-populated based on the scenario and probability of occurrence of the scenario.

- Consequence to Asset: Helps you analyze the impact of the

incident on the asset.

- Asset: Select the scenario that defines the impact on the asset.

- Likelihood: Select the probable occurrence of the scenario.

- Risk Level: Risk level is auto-populated based on the scenario and probability of occurrence of the scenario.

- Consequence to Environmental: Helps you analyze the

impact of the incident on the environment.

- Environmental: Select the scenario that defines the impact on the environment.

- Likelihood: Select the probable occurrence of the scenario.

- Risk Level: The risk level is auto-populated based on the scenario and probability of occurrence of the scenario.

- Consequence to Reputation: Helps you analyze the impact

of the incident on the stature and fame of the organization.

- Reputation: Select the scenario that defines the impact on the reputation because of the incident.

- Likelihood: Select the probable occurrence of the scenario.

- Risk Level: The risk level is auto-populated based on the scenario and probability of occurrence of the scenario.

Note:You can configure the values for Consequence and Likelihood fields using RACE to determine the Risk Level for the category.

- Consequence to People: Helps you analyze the impact of

the incident on people.

- Functional Location: Select Functional Location from the list.

After selecting the functional location, tap the Hierarchy

-

Tap the

icon to create a measurement

document for the Equipment that is entered in the Notification.

(Optional).

icon to create a measurement

document for the Equipment that is entered in the Notification.

(Optional).

-

Tap Save.

Note:You can directly tap the other tabs in the Details tab to fill the other details and save later once all the required details are filled.

-

Tap Yes in the notification creation confirmation screen.

A message appears confirming that the Notification <number> is created successfully.

Note:- In the pop-up screen, tap View NO List to navigate to the record that is created.

- You can edit the service notification details at any point before the service notification is marked complete from the same screen by tapping the Edit button.