Add Operations

An operation is a specific task or step within a Work Order that must be completed as part of maintenance or repair work. Instead of assigning the entire Work Order to a single technician, Operations helps divide a work order into logical units based on the nature of the work and assigns each operation to a technician based on expertise.

- Better Task Distribution: Supervisors can assign different operations to technicians based on their expertise.

- Faster Completion: Splitting a work order into multiple operations ensures work progresses simultaneously, reducing downtime.

- Flexibility: Operations can be reassigned to other technicians in case of emergencies or technician unavailability.

A Work Order for servicing an industrial pump could be divided into the following multiple operations:

- Electrical Check (Assigned to an Electrician): Inspect wiring, check motor connections, and test voltage levels.

- Mechanical Inspection (Assigned to a Mechanic): Check for leaks, inspect seals, and ensure the pump’s alignment.

- Lubrication (Assigned to a Maintenance Technician): Apply lubricants to bearings and moving parts.

- Final Testing (Assigned to a Supervisor or Senior Technician): Run the pump, check performance, and approve completion.

Each technician works on their assigned operation, ensuring the job is completed efficiently and correctly. If an emergency arises (for example, the electrician is unavailable), their operation can be reassigned to another qualified electrician.

Not all operations within a work order require a technician to be assigned individually. Even if no technician is assigned at the operation level, the person assigned to the overall work order can still review and confirm those operations.

This allows flexibility in execution—especially when certain steps don’t require a specialist or when the work order is handled end-to-end by a single technician.

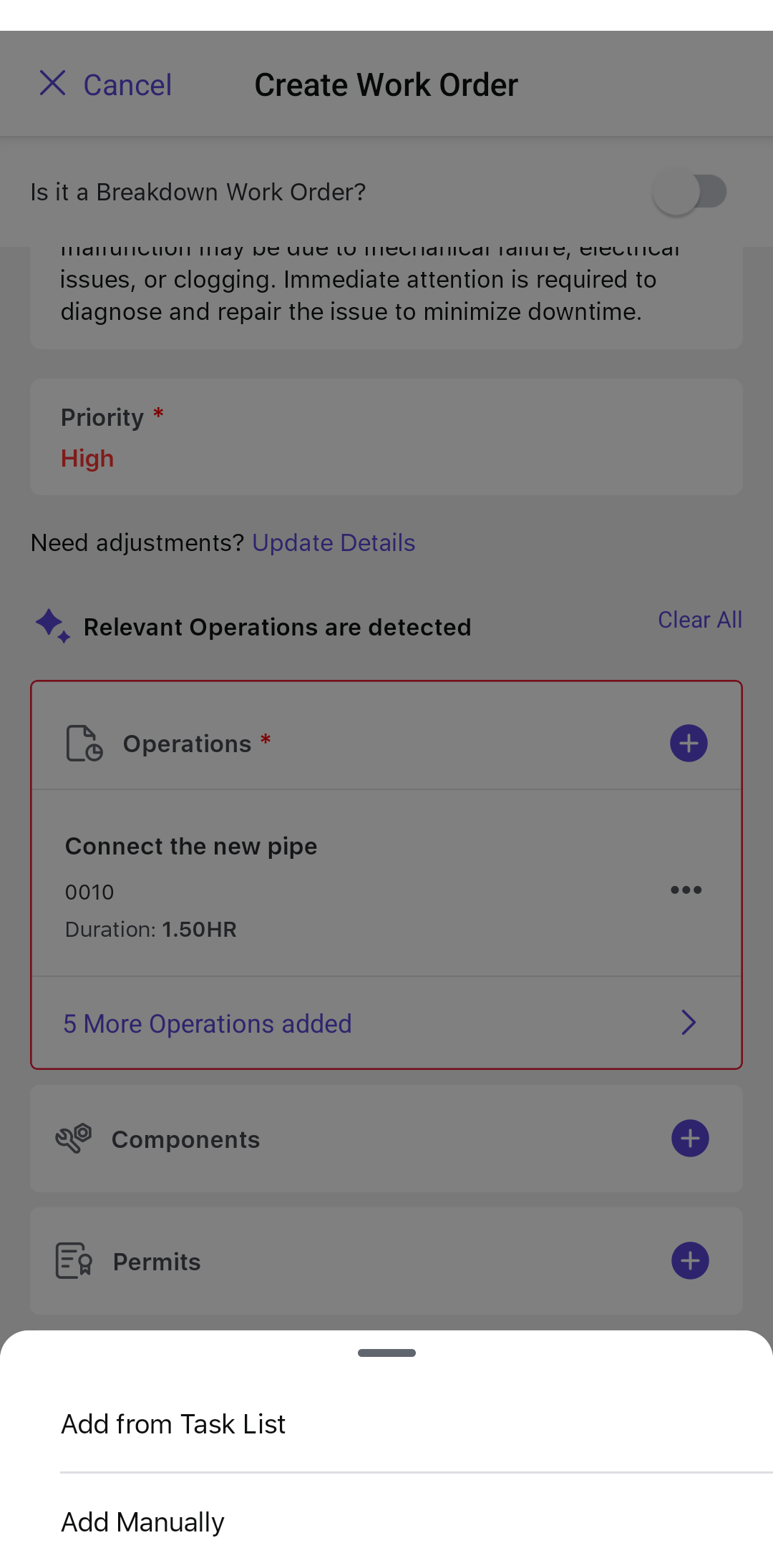

To add operations to the work order:

-

In the Operations section, tap the Add

icon.

A pop-up is displayed with the following options:

icon.

A pop-up is displayed with the following options:- Add Task from Task List

- Add Manually

Figure 1. Add Operations

-

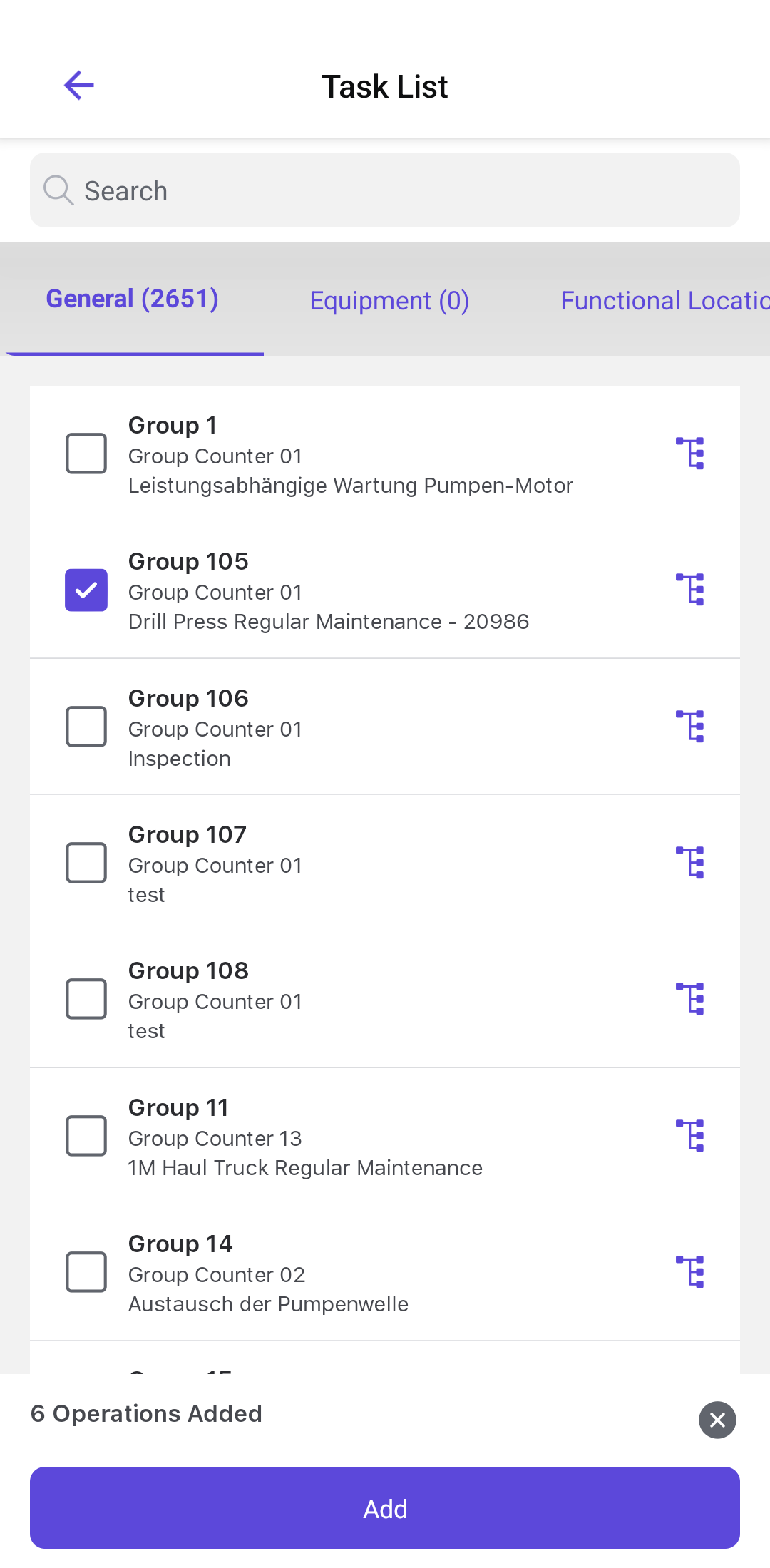

If you select Add Task from Task List, do the following:

- Choose the relevant operation from the list in the General,

Equipments, or Functional Locations tab.Note:

- Tabs are only displayed if they contain operations.

- If a tab (General, Equipment, or Functional Location) has no operations, it is hidden.

- If none of the tabs have operations, the entire section is hidden and the following message is shown: “No Operations are present in the tasklist.”

Figure 2. Add Operations From Task List

- Tap the Add button.

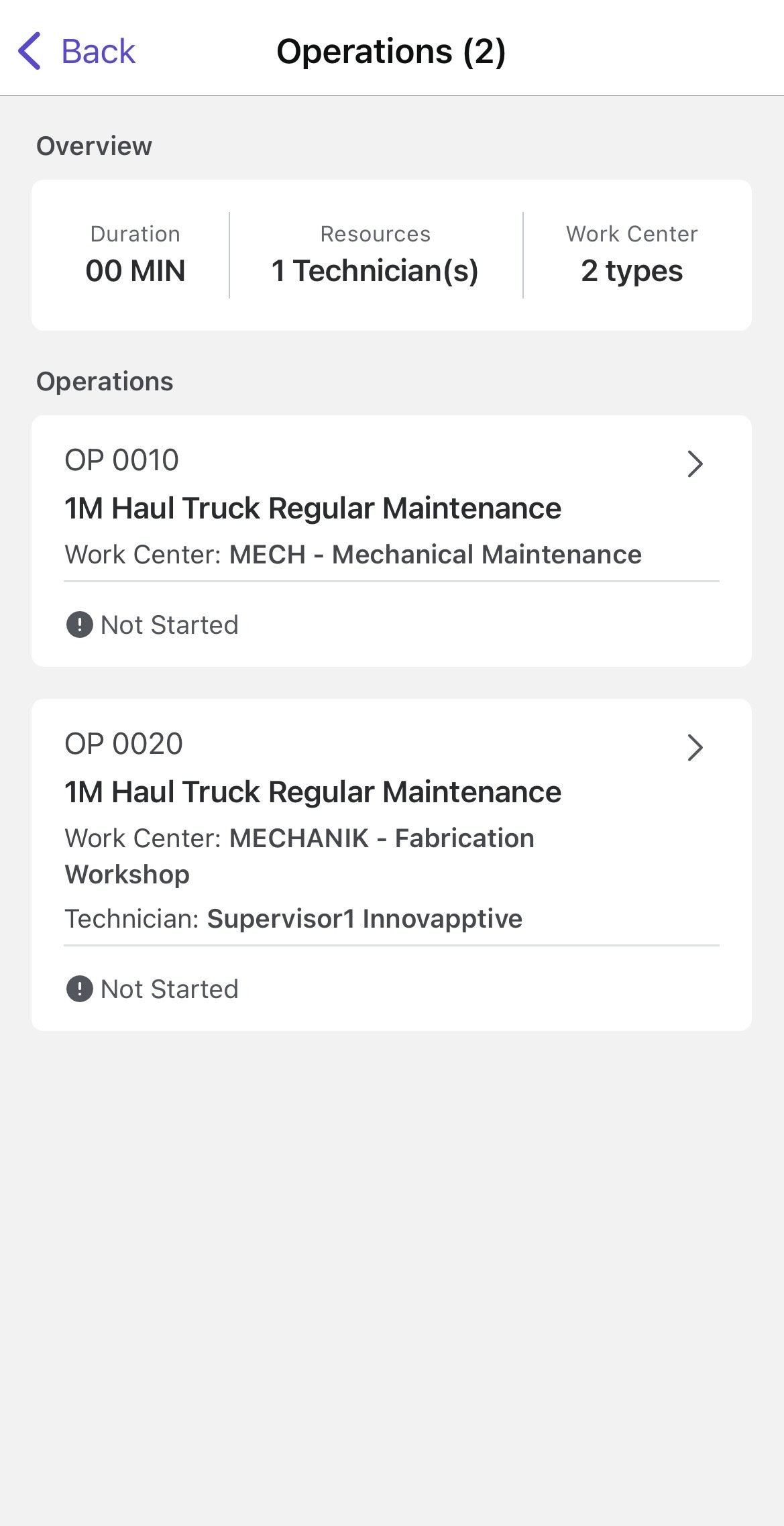

- In the Operations screen, you can view the list of

operations.

Figure 3. Operations Screen

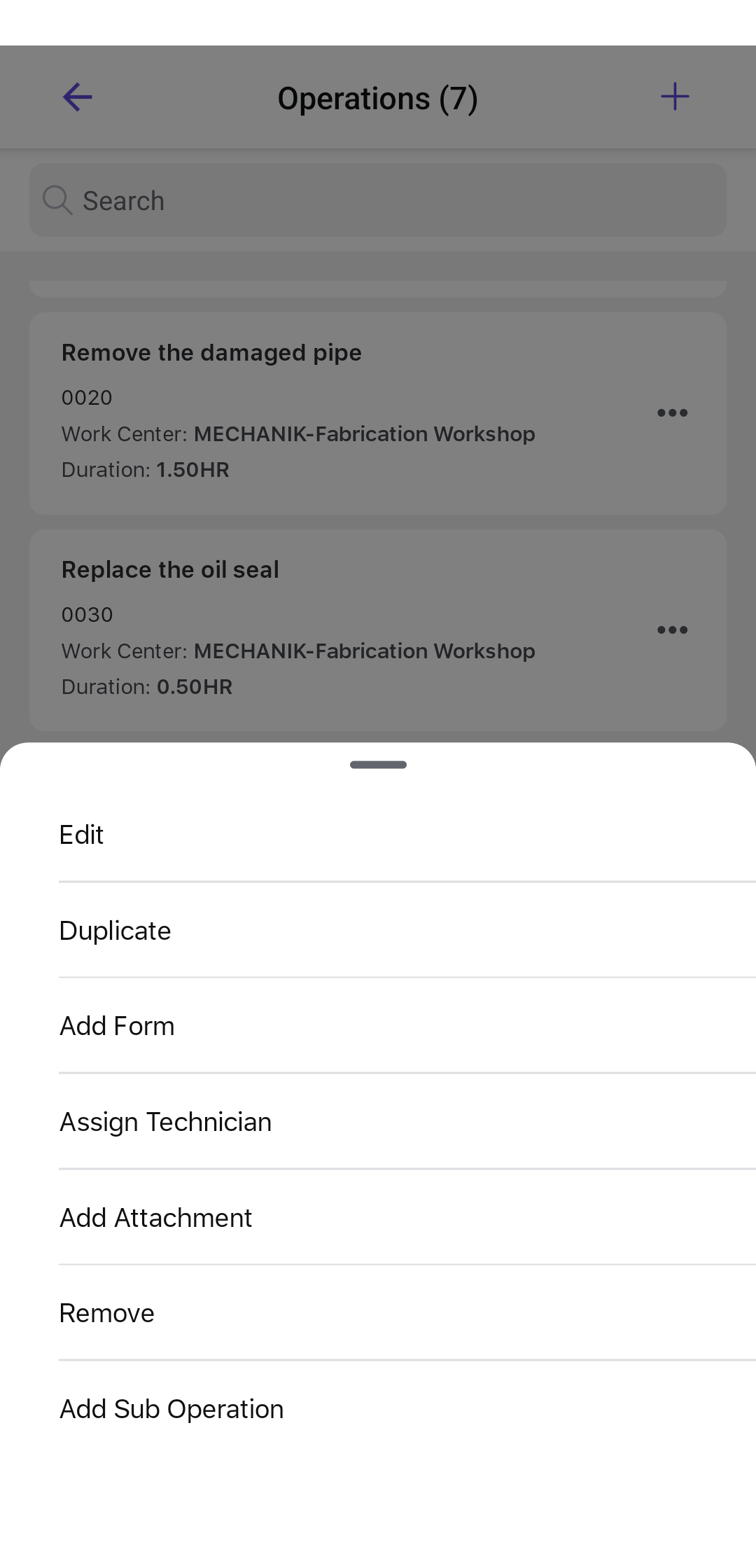

- To modify details, tap the More

icon next to the operation and select

Edit.

icon next to the operation and select

Edit.Figure 4. More Options

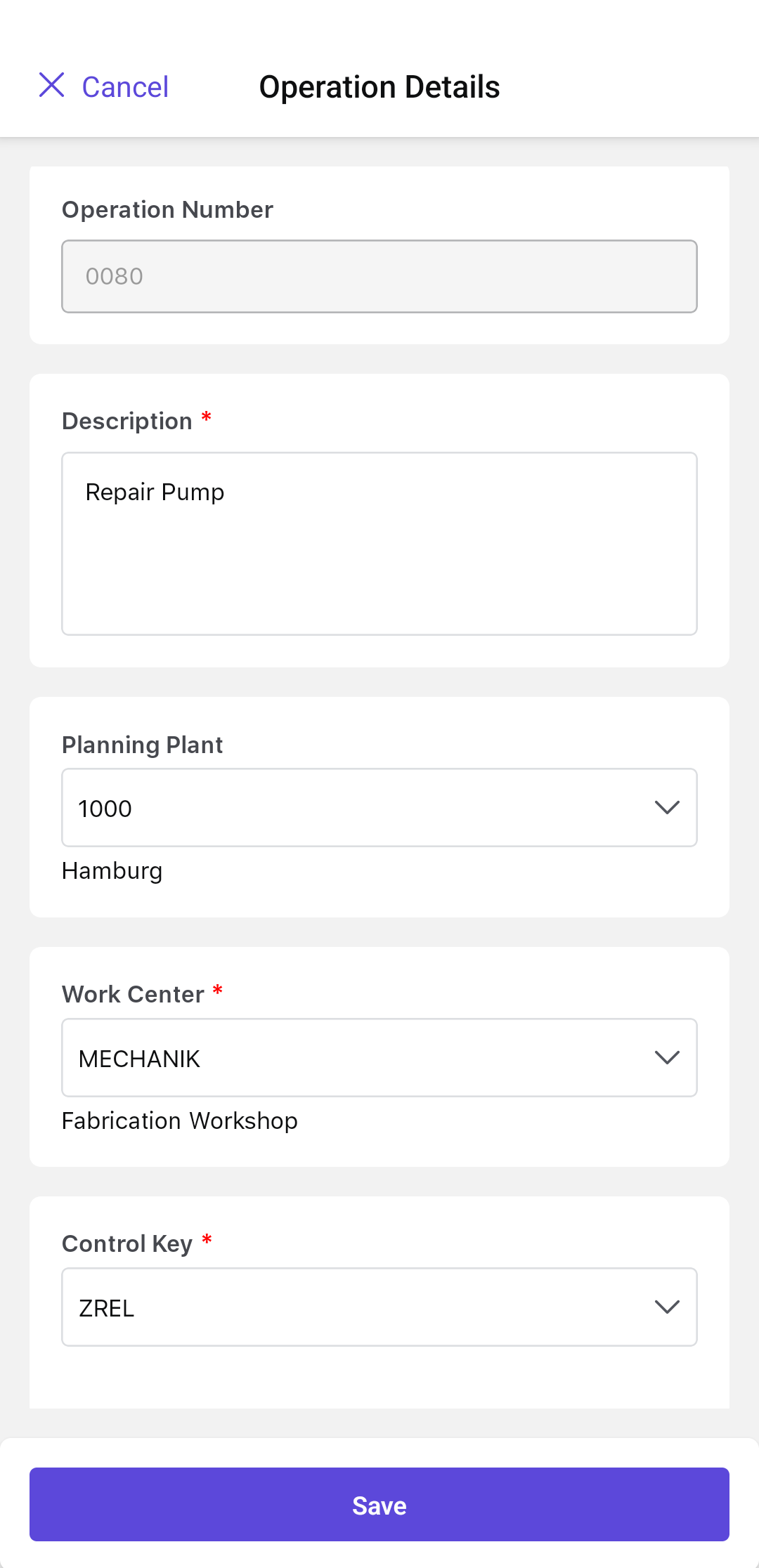

- In the Operation Details screen, you can modify the following

details:

- Description

- Planning Plant

- Work Center

- Control Key

- Plant

- Activity Type

- Number of Resources

- Duration

- Work

- Equipment

- Functional Location

Figure 5. Edit Operation Details

- Tap Save.

- Once all the operation details are filled in, tap Done.

In the Operations screen, you can tap the More

icon and select,

icon and select,- Duplicate to duplicate the operation.

- Add Form to add forms from the list.

- Assign Technician to assign the technician.

- Add Attachment to add relevant attachments such as images, videos, and documents.

- Remove to delete the operation.

- Add Sub Operation to add a sub-operation.

- Choose the relevant operation from the list in the General,

Equipments, or Functional Locations tab.

-

If you select Add Manually, do the following:

- In the Operation Details screen, fill in the details and tap Save.