Create a Follow-up Issue

During maintenance or repair work, you might come across additional problems that weren’t part of the original work order.

Use the Create Follow-up Issue option to log these findings right away, so supervisors are notified and the issue can be tracked and fixed without delay.

For example, while replacing a pump motor, you notice that the nearby pipe has a small leak. Instead of writing it down to report later, you can log it as a follow-up issue on the spot. The supervisor is alerted immediately, and the issue stays open in the system until it’s resolved.

Follow-up issues noted on paper or left to memory are easy to forget and could lead to serious breakdowns if not addressed in time.

By logging them in the system, you help catch and fix problems early—avoiding costly downtime, reducing the backlog, and making maintenance more proactive.

To create a follow-up issue:

- Open the work order.

-

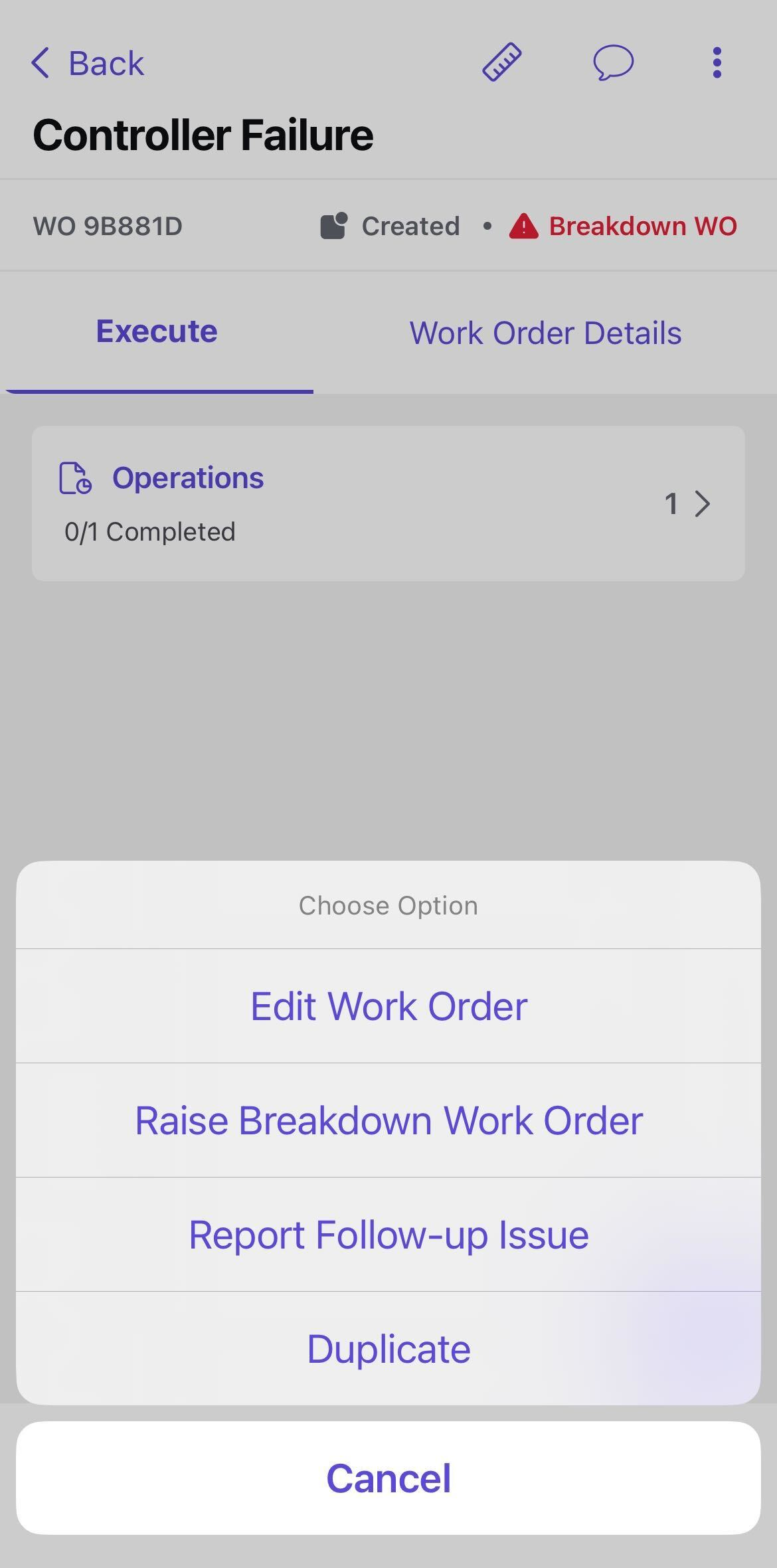

Tap the More

icon in the top-right

corner.

icon in the top-right

corner.

-

Select Report Follow-up Issue.

Figure 1. Raise Follow-up Issue

- In the Report Follow-up Issue screen, add the issue details, such as equipment, functional location, and severity, in the AI Assistant text box. For more information, see Create an Issue.

View Follow-up Issues

Once you've created the follow-up issue:

- Return to the Work Order Details screen.

-

Tap the Follow-up Issues section to view linked

issues.

Note:

- If there is only one follow-up issue, its details will open directly.

- If no issues are linked, the Follow-up Issues section will not be visible.

Delink a Follow-up Issue from the Work Order

If an issue has been incorrectly linked to a work order, you can remove (delink) it:

- In the Work Order Details screen, tap Follow-up Issues.

- Select the issue from the list that you want to remove.

- Tap the More icon next to the issue.

- Select Delink from Work Order.

- In the confirmation pop-up, tap Delink.